In this industry, the pipes and tubing are sized in two measurements:

- Outer Diameter (OD) – sometimes also called Outside Diameter, typically used for smaller fittings - most common options 1/4, 3/8, or 1/2 inch.

- Most of the time, you can find the OD tubing size marked in fine print on the sides.

- To measure the OD of a piece of pipe, measure the entire width of the pipe from the outside.

- Inner Diameter (ID) - also known as Copper Tube Size (CTS) or Minor Diameter, based on the nominal size of the pipe - most common options 1/4, 3/8, or 1/2 inch.

- The nominal size of a pipe is the internal diameter, the width of the actual waterway, instead of the full diameter of the pipe itself.

- When you measure the ID tubing size, it is based on the internal size, so be sure to exclude the width of the pipe sidewall and only measure the inner space.

Reference: https://www.freshwatersystems.com/blogs/blog/pipe-dimensions-and-nominal-pipe-size

Determining your thread type and pipe size:

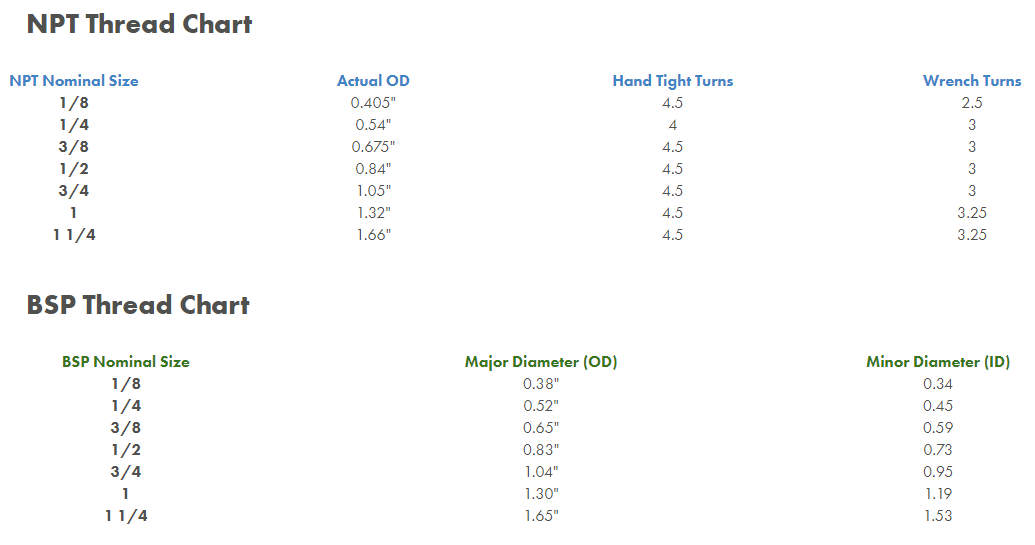

- If you live in the US, you would most likely have an NPT or NPS thread. If you’re in the EU, you would likely have a BSM thread. These are two different thread types, and they must not be mixed. Forcing an NPT or NPS thread to fit a BSM fitting will cause permanent damage and likely destroy the parts or fixture.

- Is it male or female? The male end will compress or thread into the female end. Male and female fittings are mated pairs – often this will be called a union – and for proper install the male fitting thread into a female fitting.

- Are the threads tapered or straight? A tapered thread end decreases in size as it reaches the end of the pipe or fitting, similar to the shape of a traditional wood pencil after sharpening. A straight thread remains the same size to the end, similar to the shape of a can of veggies.

- What are the ID and OD sizes? You will need to match the measurement to a thread chart to find the nominal size. (Shown below)

Reference: https://www.freshwatersystems.com/blogs/blog/how-to-determine-pipe-thread-type-and-pipe

Tips:

- Brush and clean the ends of your fittings and threads first

- Don't overtighten - you can easily crack or distort the fittings

- Don't cross your threads - once you feel it's turning incorrectly, please stop, back the fitting out, and start over

- Recommend only use Teflon tape

Comments

0 comments

Please sign in to leave a comment.